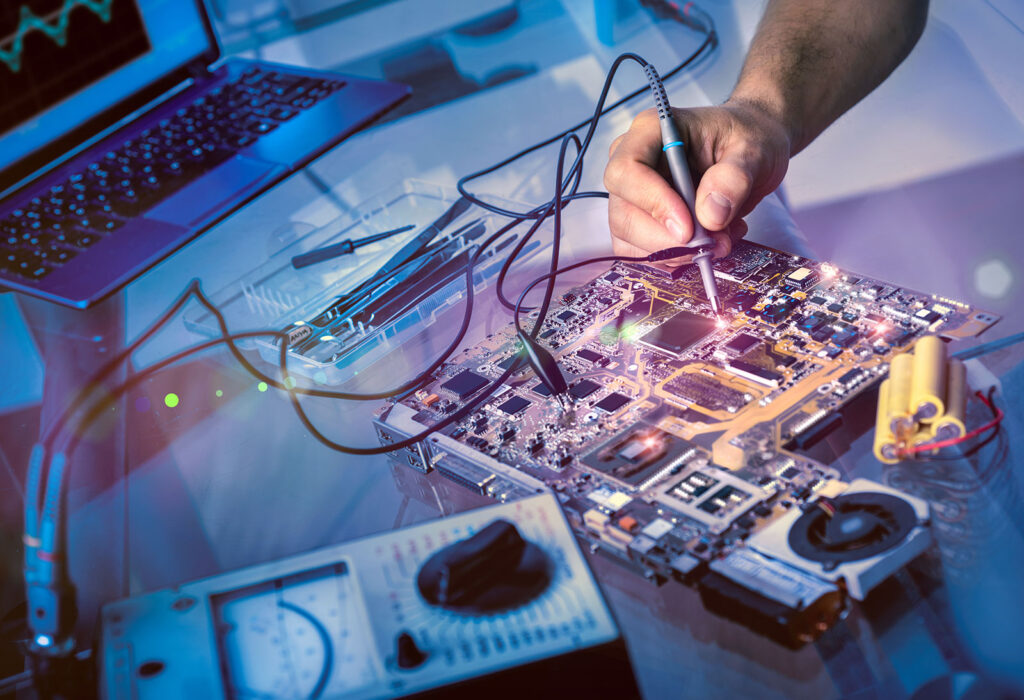

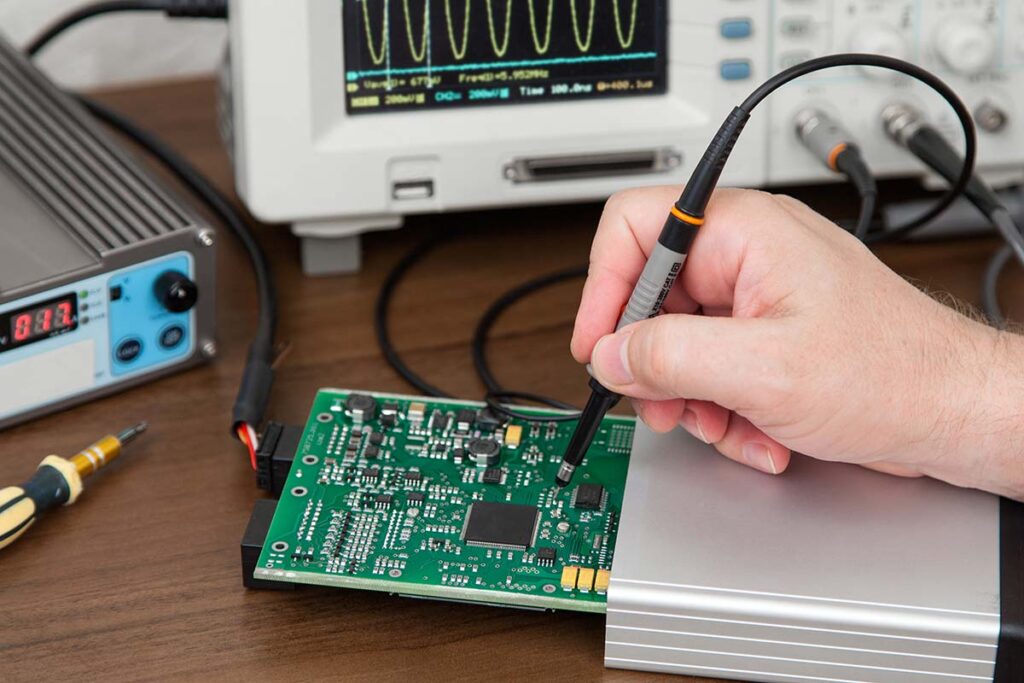

As designers, one of the things we bring to the table is experience with testing. The high bar of agency testing is between you and your customers. We have the equipment and experience required to test your product. We own advanced test and diagnostic tools to minimize the time to find errors and provide solutions. Our tools include logic analyzers, JTAG debuggers, oscilloscopes, and an assortment of meters. We also have a full suite of EMC test equipment. We have experience designing custom automated test systems for manufacturing operations. Our software tools include code coverage (VectorCAST) and other assorted test programs. All embedded products we design utilize the services described below:

Software Functional Testing

We implement a preliminary test plan based on the design specification, and a final test plan after the details of the product are understood. Diagnostics to test the initial prototype are the highest priority.

Our software testing includes:

- Code Coverage

- Code Complexity

- Unit Testing

- Use Case Testing

- FMEA

- Fuzz Testing

- BIST

Hardware Functional Testing

We provide a preliminary test plan based on the design specification, and a final test plan after of previewing the product.

Our hardware testing includes:

- White Box Testing

- Black Box Testing

- Accelerated Life Testing

- FMEA – Failure Modes and Effects Analysis

- Environmental testing

- NIST Traceable lab equipment

- MTBF – Mean Time Between Failure

Test Documentation And Traceability

We believe that in order to get the best value out of testing, you need clearly defined requirements. We can help provide this. This is why we have rigorous documentation and traceability in our testing efforts.

Our test documentation effort includes:

- Test Requirements

- Test Plans

- Test Reports

- Functional Test Cases

- Regression Test Cases

- Test Result Sign-off

Environmental Testing

We have an on-site environmental chamber to meet environmental testing need for your product. Our environmental chamber is NIST traceable for UL conformance testing.

- Environmental Chamber Specification:

- Temperature: -40°C to +200°C

- Humidity: 5% to 98%

- Workspace Dimensions : 30” W x 36” H x 32” D

We can certify your product for the following tests:

Electrical fast transient/burst (EFT) immunity

Electrostatic discharge (ESD) immunity

- Immunity to conducted disturbances

- Conducted emissions

- Surge immunity

- Voltage dips, short interruptions and voltage variations immunity

- High Potential safety (Hi-Pot)

Tools

- Jira – Bug tracking

- VectorCast – Code coverage

- N unit – Automation testing software

- LabVIEW – Test control software

- X-ray – Test case management

- Relyance – MTBF software

Cybersecurity

How do you know if your product or system is secure? By testing it. We preform the following types of penetration testing:

- White box testing

- Black box testing

- Red Team / Blue Team

- OWASP

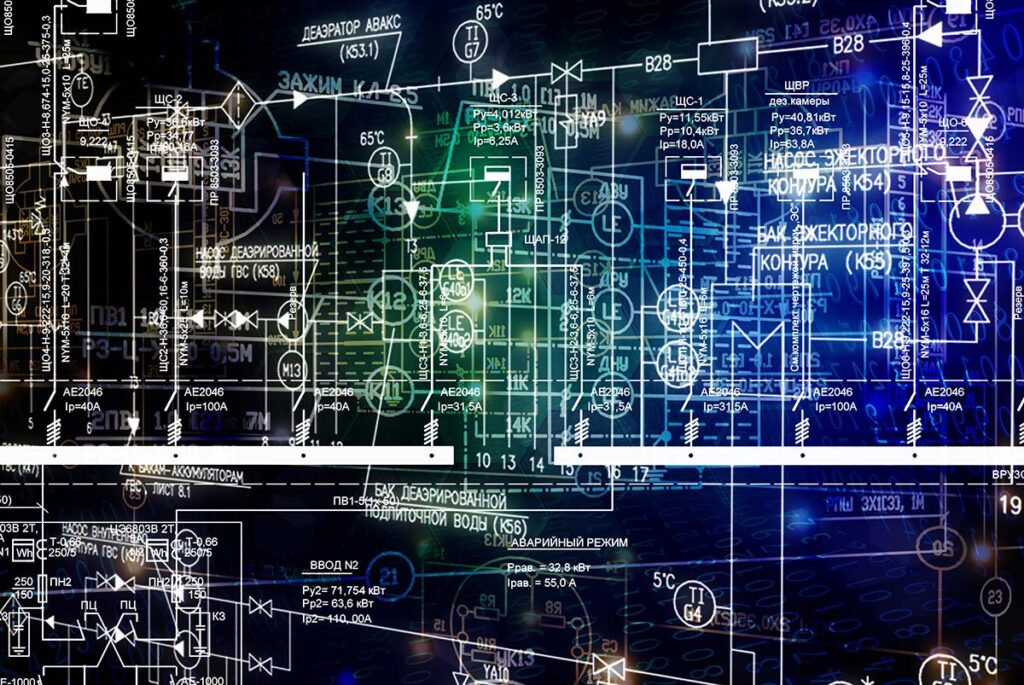

PCB Design Simulation

HyperLynx SI (Signal Integrity) – performs signal integrity analysis using automated workflows. Performs “what-if” analysis and supports general-purpose SI, DDR interface signal integrity and timing analysis, power-aware analysis and compliance analysis.

HyperLynx PI (Power Integrity) – is used to identify potential power integrity distribution issues that can interfere with board design logic. It helps to reduce prototype spins, shorten time to market, and allows development of more reliable products.

SOLIDWORKS Flow Simulation – A computational fluid dynamics program used to identify hot spots and heat transfer inside products and optimize heat dissipation.

ModelSim combines simulation performance and capacity with the code coverage and debugging capabilities required to simulate multiple blocks and systems and attain ASIC gate-level sign-off in Verilog, VHDL, and SystemC.

Automated Test Systems

We design, implement, and verify automated test platforms for both hardware and software products in both the development lifecycle and manufacturing. We create unit tests for software products using tools such as CUnit, JUnit, NUnit, and Robot Framework for C, C++, Java, C#, and Python. We employ continuous integration (CI/CD) with build systems such as Jenkins for rapid development and bug remediation. For manufacturing, we create custom electromechanical fixtures and software and/or integrate National Instruments’ LabView to test and calibrate subcomponents and final assemblies of products.

Manufacturing Testing

We design and build testing rigs to support manufacturing efforts. We also provide detailed work instructions for use by manufacturing technicians.

Testing For Regulatory Agency Certification And Approvals

NAM has extensive experience with the equipment and systems testing required to attain certification and approvals required by US and international agencies and regulatory bodies. NAM will guide you through the process to ensure that you have the necessary reports and documentation needed for approval.

NAM has experience with obtaining certification and approval for the following:

UL -Underwriters Laboratories, A US company that drafts safety standards for electrical equipment. They certify and tests products for electrical safety

CE– Conformite Europeene or European Conformity. A mandatory marking for products sold in Europe. Similar to FCC Declaration of conformity. The CE marking indicates that the product complies with directives in relation to ‘Electro Magnetic Compatibility, meaning the device will work as intended, without interfering with the use or function of any other device.

MIL-STD-810 – The MIL-STD-810 test method standard for environmental engineering considerations and laboratory tests is a publication of the US Department of Defense with contributions from the US Army, Air Force, and Navy as well as the Institute of Environmental Sciences and Technology (IEST) and the Shock and Vibration Information Analysis Center (SAVIAC).

ATEX– a European Directive describing what equipment and work environment is allowed in an environment with an explosive atmosphere.

FCC– Federal Communication Commission. They regulates interstate and international communications by radio, television, wire, satellite and cable in all 50 states, the District of Columbia and U.S. territories. An independent U.S. government agency overseen by Congress, the commission is the United States’ primary authority for communications law, regulation and technological innovation. They set the declaration of conformity of with accredited testing laboratory for radiated emissions.

IEC – International Electrotechnical Commission, a non-profit, non-governmental international standards organization that prepares and publishes International Standards for all electrical, electronic and related technologies. IEC standards in the IEC 61000 family are used to ensure compliance with the EMC Directive.

NEMA – National Electrical Manufacturers Association (NEMA) defines standards used in North America for various grades of electrical enclosures typically used in industrial applications. Each is rated to protect against personal access to hazardous parts, and additional type-dependent designated environmental conditions. A typical NEMA enclosure might be rated to provide protection against environmental hazards such as water, dust, oil or coolant or atmospheres containing corrosive agents such as acetylene or gasoline.

The IP Code – International Protection Marking – classifies and rates the degree of protection provided against intrusion (body parts such as hands and fingers), dust, accidental contact, and water by mechanical casings and electrical enclosures.

EMP– The RS105 test method specified in MIL-STD-461G addresses the risk of radiated exposure to an EMP event. RS105 testing is generally applicable for equipment installed in exposed and partially exposed environments.

The RS105 pulse characteristics consist of a fast rise time, short pulse duration, and high amplitude which resemble those of an actual EMP. Peak field strength of 50 kV/m are specified for exposed equipment. However, tailoring the peak field levels are often required for partially exposed installations due to the attenuated effects provided by enclosures